Diecasting is a versatile and widely used manufacturing process that involves introducing molten steel into a mold chamber under extreme pressure. It is extremely efficient in the production of large amounts of complicated metal parts, with high dimensional precision and smooth surfaces. Materials, processes, and the applications of diecasting are vital to a variety of industries, and it is an essential component of manufacturing today. This article will explore the basic concepts of diecasting, its advantages and diverse uses in the industry.

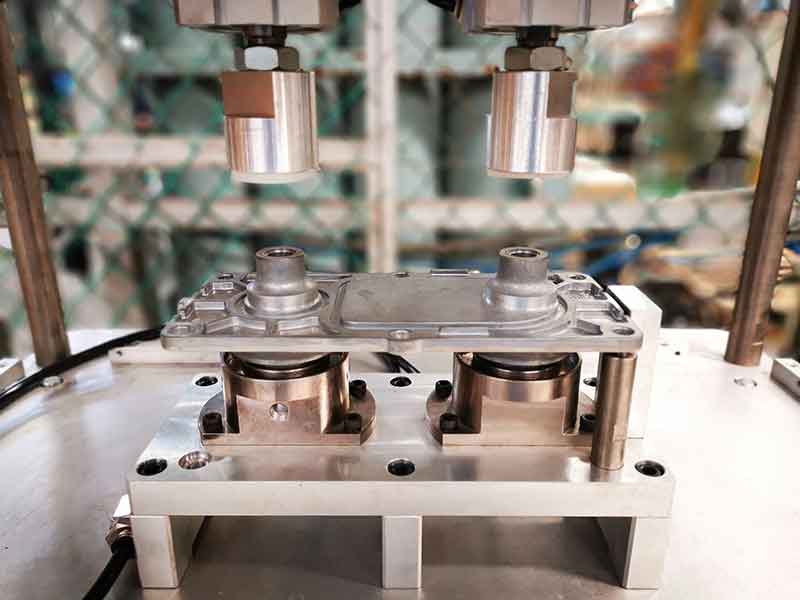

Diecasting starts with the creation of top-quality steel molds, also known as dies. These molds are created for the harsh pressures as well as the high temperatures produced by molten steel. The dies are meticulously designed to take in intricate details and keep tight tolerances making sure that every part cast has the right specifications. When casting is performed, metals such as aluminum, zinc, magnesium, and copper are melted and then put into the die with high pressures. The rapid injection process and the subsequent cooling creates parts that have high dimensions and an even top finish. The accuracy of the dies allow for the development of parts with intricate geometries that are usually impossible using other processes of manufacture.

One of the major benefits of diecasting is its efficacy in mass production. When the dies are made, they can be used to produce thousands of identical parts that are identical with little variation. This degree of precision is crucial for businesses which require huge quantities of consistent parts. In addition, diecasting is renowned for its high efficiency of materials. It produces little scrap, because any excess metal can be recycled and reused for subsequent casting cycles. It not only lowers cost of materials but also helps to promote green manufacturing methods by reducing production waste while also conserving resources. The combination of high efficiency, high speed as well as material efficiency make diecasting an attractive option for companies looking to improve their processes for production.

Diecasting can also provide significant advantages regarding mechanical properties. The components that are made by diecasting usually have excellent durability and strength because of the fine-grain structure formed during the rapid cooling of molten metal. Diecasting makes them perfect for use in applications that require high performance and reliability. Furthermore, this process permits to integrate thin walls and complex elements without compromising their structural integrity. This can be particularly beneficial in the automotive and aerospace industries, where reducing weight and retaining strength is crucial. It is possible to make lightweight, yet strong components can improve the efficiency of fuel and the performance of vehicles and aircraft. To receive further information kindly go to https://www.senadiecasting.com.my/

The choice of materials in diecasting can significantly affect the physical properties and performance of the final product. Aluminum is the most popular material due to its outstanding strength-to-weight ratio, resistance to corrosion, and thermal and electrical conductivity. Aluminum’s properties make it ideal in aerospace and automotive industries in which weight reduction is essential. Zinc alloys have high strength as well as ductility. These make them ideal for components that require fine details and durability. Magnesium alloys are the lightest metallic structural elements, offering the advantage when weight savings are paramount. Copper alloys are typically used in less applications, are valued for their excellent electrical conductivity as well as their resistance to corrosion. Each metal has unique advantages that allow manufacturers to choose the most suitable option to meet the specific requirements of their application.

Diecasting is an extremely effective and adaptable manufacturing process that’s essential in the creation of sophisticated metal parts with consistent and high-precision. Its capacity to design components with fine details as well as tight tolerances and smooth surface finishes makes it invaluable across various sectors, from automotive to aerospace to consumer electronics and even beyond. Its use of various materials further enhances the versatility that diecasting offers, allowing companies to select the ideal alloy for their specific needs. Technology advances, and the demand for high-quality, cost-effective components continues to grow and increase, diecasting will continue to be an essential element for manufacturing, driving innovation and excellence in production.